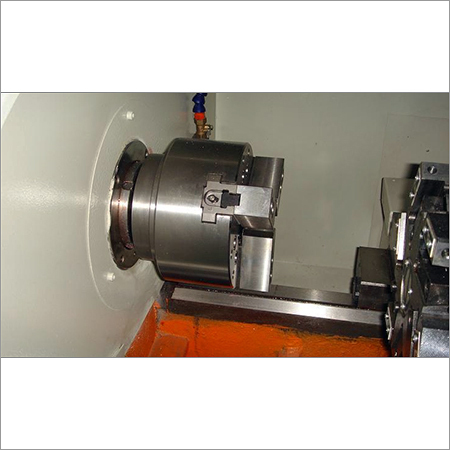

Used CNC Profile Cutting Machinery

Used CNC Profile Cutting Machinery Specification

- Output

- Optimized CNC profiling for steel, mild steel, aluminum

- Used For

- Cutting metal plates with CNC automation

- Color

- Blue & Yellow

- Weight

- Approx. 2200 kg

- Manufacturing Year

- 2018

- Condition

- Used

- Origin

- Imported

- Voltage

- 380V

- Machine Type

- CNC Profile Cutting Machine

- Dimension (L*W*H)

- 4500 mm x 1600 mm x 1700 mm

- Capacity

- Up to 100 mm plate thickness

- Power

- 11 kW

Used CNC Profile Cutting Machinery Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- Delhi

About Used CNC Profile Cutting Machinery

To meet the diversified requirements of our prestigious clients, we are engaged in offering Used CNC Profile Cutting Machinery that is sourced from reliable sources of the industry. Provided machinery is maintained under the supervision of our vendors experts by replacing damaged components with original ones. Offered machinery is used in automobile, construction and engineering industries for profile cutting applications. This Used CNC Profile Cutting Machinery is available in different specifications at highly competitive prices.

Key Features:

- Long service life

- Hassle free operation

- Less maintenance

- High performance

Remark: Taiwan Chandox is No.1 Brand of Chuck&Cylinder Industry Area in China Mainland

Advanced Servo-Driven Precision

The machines drive system incorporates high-quality servo motors across both X and Y axes, providing reliable control and movement for intricate profile cutting. This allows users to achieve impressive cutting speedsup to 6000 mm/minwhile maintaining a tight accuracy tolerance of 0.5 mm. The automatic torch height control further enhances cut quality and reduces operator workload.

Versatile Cutting Capacity

Supporting materials such as steel, stainless steel, and aluminum plates, the system is engineered to handle a maximum thickness of 100 mm. The sizable table (3000 mm x 1500 mm) accommodates large workpieces, making it suitable for diverse industrial projects requiring flexibility in both scale and material.

User-Focused Industrial Automation

With an integrated CNC controller and included essential accessories (gas regulators, plasma consumables, and cable set), setup and operation are streamlined. The automated features and built-in cooling system maximize uptime and machine longevity, while the machines ergonomic dimensions and manageable weight simplify site integration and handling.

FAQs of Used CNC Profile Cutting Machinery:

Q: How does the automatic torch height control function benefit the cutting process?

A: The automatic torch height control maintains optimal distance between the cutting torch and material surface, adjusting in real-time to variations in plate flatness. This ensures clean, consistent cuts, reduces nozzle wear, and minimizes manual intervention, improving overall productivity and accuracy.Q: What types of materials can this used CNC Profile Cutting Machine process?

A: This machine is designed to cut a variety of metal plates, including steel, stainless steel, and aluminum. It can handle materials up to 100 mm in thickness, making it suitable for numerous fabrication and manufacturing applications.Q: When was this CNC profile cutting machine manufactured, and how much has it been used?

A: Manufactured in 2018, this machine has approximately 4000 operational hours. It has been well-maintained and remains in reliable used condition, ready for immediate deployment in production environments.Q: Where can this machine be installed and used most effectively?

A: Designed for industrial settings, this CNC Profile Cutting Machine is ideal for metalworking shops, fabrication facilities, and manufacturing plants that require precise and automated plate profiling. Its manageable dimensions and integrated systems facilitate smooth installation and operation.Q: What is the typical process for operating the CNC profile cutting machine?

A: Users prepare digital cutting profiles or drawings, set up the material on the 3000 mm x 1500 mm table, and input cutting parameters via the CNC controller. The servo-driven axes and automatic height control ensure precise, automated cutting according to specified designs, efficiently producing the required parts.Q: What accessories are included with this used CNC profile cutting machine?

A: The machine is supplied with essential accessories: gas regulators, plasma consumables, and a cable set, ensuring you have the necessary components to commence operations without delay.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used CNC Machinery Category

Heavy Duty Used CNC Machine

Price 400000.00 INR

Minimum Order Quantity : 1 Unit

Machine Type : Heavy Duty Used CNC Machine

Origin : Imported (Europe)

Weight : 4500 kg

Condition : Used, Good Working Condition

Used Industrial CNC Machine

Price 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Machine Type : CNC Vertical Machining Center

Origin : Germany

Weight : Approx. 3200 kg

Condition : Used

Used CNC Vertical Machine

Price 400000.00 INR

Minimum Order Quantity : 1 Unit

Machine Type : CNC Vertical Machine

Origin : Imported

Weight : 3900 kg

Condition : Used

Used CNC Machine

Price 400000.00 INR

Minimum Order Quantity : 1 Unit

Machine Type : CNC Milling Machine

Origin : Imported

Weight : 2500 kg

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese