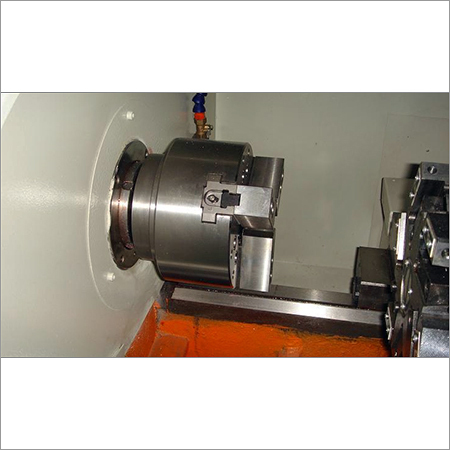

Heavy Duty Used CNC Machine

Heavy Duty Used CNC Machine Specification

- Output

- Precision Machined Metal Components

- Color

- Grey

- Manufacturing Year

- 2016

- Condition

- Used, Good Working Condition

- Weight

- 4500 kg

- Voltage

- 380 V

- Capacity

- Multiple Operations, Handles Heavy Components

- Dimension (L*W*H)

- 3200 mm * 2100 mm * 2400 mm

- Machine Type

- Heavy Duty Used CNC Machine

- Power

- 15 kW

- Origin

- Imported (Europe)

- Feature

- High Rigidity, Robust Structure, Reliable Performance

- Used For

- Industrial Metalworking, Precision Machining

Heavy Duty Used CNC Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- Delhi

About Heavy Duty Used CNC Machine

Keeping track with the latest market developments, we are engaged in offering an extensive range of Heavy Duty Used CNC Machine. Provided machine is widely used for heavy material cutting, milling and turning applications in different industries like automobile, automotive and many more. By following industry defined guidelines, our vendors repair this machine by replacing damaged parts with premium grade components with the aid of latest techniques. Also, it is rigorously tested to ensure its high performance at clients end. In tune with clients diverse requirements, we offer this Heavy Duty Used CNC Machine in different specifications.

Key Features:

- Rugged design

- High operational fluency

- Unmatched performance

- Low power consumption

Remark: Taiwan Chandox is No.1 Brand of Chuck&Cylinder Industry Area in China Mainland &Taiwan

Precision Meets Power

Achieve unmatched accuracy and productivity with this robust used CNC machine, perfect for demanding industrial applications. Its 1200 mm X-axis travel, 1800 kg table load, and high repeatability provide optimal results for precision machining projects, making it a reliable choice for manufacturers tackling complex metal components.

Integrated Systems for Smooth Operation

Experience advanced operational capabilities with an automatic centralized lubrication system and an integrated coolant tank and pump. These features minimize downtime, reduce maintenance requirements, and maintain optimal working conditions for prolonged machine lifespan and reliable output.

User-Friendly Interface and High Versatility

The CNC machine is equipped with a modern touchscreen panel that simplifies process control and monitoring. Its tool magazine supports up to 24 tools, allowing seamless transitions between operations and accommodating various metalworking techniques across steel, cast iron, and aluminum alloys.

FAQs of Heavy Duty Used CNC Machine:

Q: How does the CNC machine handle heavy workpieces and complex machining tasks?

A: With a table load capacity of 1800 kg and robust axis travels (X: 1200 mm, Y: 700 mm, Z: 600 mm), this machine efficiently manages large and heavy components, making it ideal for intricate industrial metalworking and precision machining applications.Q: What materials can be processed with this CNC machine?

A: The machine is engineered to handle a range of materials, including steel, cast iron, and aluminum alloys, delivering precise results and adaptability across various industrial manufacturing needs.Q: When is maintenance required, and how is it facilitated?

A: Routine maintenance intervals depend on usage intensity, but the integrated automatic centralized lubrication and coolant system significantly reduce manual maintenance while ensuring all moving components remain protected and operational.Q: Where was this CNC machine manufactured and what is its origin?

A: This heavy-duty CNC machine is an imported solution from Germany, recognized for its engineering excellence and durability, and is available through suppliers and traders in India.Q: What benefits does the touchscreen operator interface provide?

A: The touchscreen panel offers user-friendly control, simplifying machine setup, program selection, and process monitoring for operators, which increases productivity and reduces the learning curve for new users.Q: How does the machine ensure consistent and precise output?

A: High rigidity, robust structure, repeatability within 0.008 mm, and automatic lubrication contribute to consistent precision, making this CNC machine reliable for producing high-quality, repeatable metal components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used CNC Machinery Category

Used Industrial CNC Machine

Price 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Light Grey & Blue

Machine Type : CNC Vertical Machining Center

Weight : Approx. 3200 kg

Condition : Used

Used CNC Profile Cutting Machinery

Price 400000.00 INR

Minimum Order Quantity : 1 Unit

Color : Blue & Yellow

Machine Type : CNC Profile Cutting Machine

Weight : Approx. 2200 kg

Condition : Used

AMS WINNER VMC

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Color : BLUE AND WHITE

Machine Type : VERTICAL MACHINING CENTER

Weight : 4400KG Kilograms (kg)

Condition : GOOD

LEADWELL MCV 610S VMC

Price 700000 INR / Number

Minimum Order Quantity : 1 Number

Color : GREEN

Machine Type : New

Weight : 3600 KG Kilograms (kg)

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese