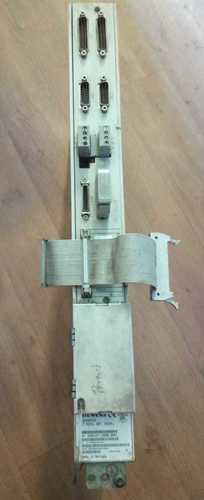

Vickers Axis Drive

Vickers Axis Drive Specification

- Dimension (L*W*H)

- 210 mm x 130 mm x 95 mm

- Voltage

- 220 V AC

- Feature

- High Precision, Robust Design, Efficient Performance

- Color

- Black & Blue

- Used For

- Industrial Automation, CNC Machines, Hydraulic Systems

- Weight

- 6 kg

- Manufacturing Year

- 2023

- Output

- Digital/Analog Signal Output

- Machine Type

- Axis Drive

- Condition

- New

- Power

- 400 W

- Capacity

- Up to 3000 RPM

Vickers Axis Drive Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- Delhi

About Vickers Axis Drive

VICKERS AXIS DRIVE is a smart and intelligent motion control device that is designed to ensure high working efficiency of the servo drives for a longer period without the risk of system breakdown. It is provided with multiple pin connecting ports to make reliable physical connections with using universal power cables. The circuitry of this unit is enclosed in a sturdy enclosure to prevent damages due to harsh industrial conditions. Customers can get VICKERS AXIS DRIVE from our company in large quantities as per their demands.

- Vickers Bds4

- Model No: Bds420623412w32

- Serial No: 49988300

High-Performance and Reliable Motion Control

The Vickers Axis Drive is designed to deliver consistent, high-precision motion control for a variety of industrial applications. Its compact design and robust construction ensure longevity and optimal performance in tough manufacturing conditions. The flange mounting facilitates secure installation, while the IP65 protection guards against dust and moisture, making it suitable for continuous use in challenging environments.

Easy Integration and Maintenance-Free Operation

With standard connectivity via RS232 or Ethernet, the Vickers Axis Drive integrates seamlessly into existing automation systems. Supporting both digital and analog signal outputs as well as various input types, it offers versatile compatibility. The maintenance-free lubrication system and natural air cooling reduce downtime and operational costs, ensuring smooth, uninterrupted operation.

Precision and Safety in Every Application

Equipped with an incremental encoder for accurate feedback, the Vickers Axis Drive offers quick response times under 2 ms and handles capacities up to 3000 RPM. It is compliant with CE and ISO 9001:2015 standards, ensuring both safety and reliability. The drive is engineered to operate at 220 V AC and delivers up to 400 W of power, making it suitable for a wide range of industrial automation applications in India.

FAQs of Vickers Axis Drive:

Q: How is the Vickers Axis Drive installed in industrial machines?

A: The Vickers Axis Drive features a flange mounting design, which allows for stable and precise attachment to various industrial equipment such as CNC machines, machining centres, and press machines. Detailed installation guidelines are provided, ensuring correct alignment and secure fitting.Q: What signal and connectivity options does the Vickers Axis Drive support?

A: This axis drive supports both pulse + direction and analog input signals, and can be connected using RS232 or Ethernet interfaces. This versatility makes it compatible with a broad range of automation controllers and systems.Q: When should the Vickers Axis Drive be used over other motion drives?

A: The Vickers Axis Drive is ideal when high precision, robust design, and efficient performance are required, especially in applications such as machining centres, material handling, and press machines. Its maintenance-free operation and IP65 protection make it well-suited for continuous, intensive industrial use.Q: Where can I use the Vickers Axis Drive in industrial automation?

A: You can utilize this drive in a variety of industrial automation applications, including CNC machinery, hydraulic systems, material handling setups, and press operations. Its durable design and reliable performance make it an excellent choice for use across multiple sectors in India.Q: What are the key benefits of using the Vickers Axis Drive?

A: Key benefits include high-precision motion control, robust construction, efficient response time of less than 2 ms, maintenance-free operation, and reliable operation under harsh industrial conditions, all supported by compliance with CE and ISO 9001:2015 standards.Q: How does the natural air cooling system work in the Axis Drive?

A: The drive is engineered for natural air cooling, eliminating the need for active cooling mechanisms. This reduces maintenance requirements and provides consistent performance across its operating temperature range of 0C to 45C.Q: What process should be followed for integrating the Axis Drive into existing automated systems?

A: Begin by selecting a compatible mounting location, ensuring proper alignment. Connect the drive via RS232 or Ethernet as required, then configure the input (pulse + direction or analog) and output signal settings according to your systems requirements. Finally, test the drive to verify accurate functionality and performance within your automation process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used CNC Spares Category

Vickers Spindle Driver

Price 2000 INR / Unit

Minimum Order Quantity : 1 Unit

Output : Variable Frequency Output

Used For : Industrial CNC Machine Automation

Color : BlueGrey

Condition : New

Seimens Sinumerik 840d Screen

Price 2000 INR

Minimum Order Quantity : 1 Unit

Output : Digital Visualization of CNC Data

Used For : Sinumerik 840D CNC Machine Operations

Color : Grey/Black

Condition : New

Simodrive Lt Module

Price 2000 INR

Minimum Order Quantity : 1 Unit

Output : Varies by module, designed for servo drives

Used For : Industrial automation and drive control systems

Color : Grey

Condition : Used

Seimens Sinumerik Cpu 810d

Price 2000 INR

Minimum Order Quantity : 1

Output : Digital/Analog Output Interfaces

Used For : CNC Machine Automation

Color : Grey

Condition : Used

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese