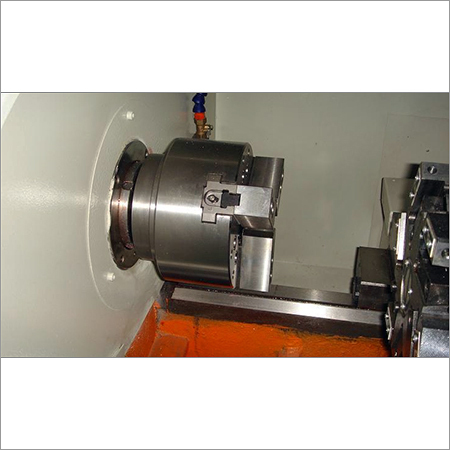

Used CNC Vertical Machine

Used CNC Vertical Machine Specification

- Color

- Gray

- Condition

- Used

- Dimension (L*W*H)

- 2750 mm x 2000 mm x 2600 mm

- Output

- Finished machined components

- Manufacturing Year

- 2014

- Machine Type

- CNC Vertical Machine

- Weight

- 3900 kg

- Origin

- Imported

- Capacity

- 750 kg workpiece

- Power

- 7.5 kW

- Used For

- Metal & precision engineering

- Feature

- High accuracy, programmable operations, robust build

- Voltage

- 380V

- Spindle Speed

- 8000 rpm

- Operating Interface

- Color LCD panel with USB and RS232 ports

- Repeatability

- ±0.005 mm

- Travel (X/Y/Z)

- 1000/500/500 mm

- Max Table Load

- 800 kg

- Number of Tool Stations

- 24 ATC

- Air Requirement

- 6 bar

- Tool Shank Type

- BT40

- Country of Supply

- India

- Table Size

- 1100 mm x 500 mm

- Enclosure Type

- Full safety enclosure

- Lubrication System

- Automatic central lubrication

- Rapid Traverse Rate

- 24 m/min

- Spindle Taper

- ISO 40

- Coolant System

- Integrated

Used CNC Vertical Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- Delhi

About Used CNC Vertical Machine

We are an acclaimed name engaged in offering our precious clients a superior quality range of Used CNC Vertical Machine. The offered machine is used for cutting, milling and turning hard material for making instruments, electronic connector, medical apparatus and many more. This machine is repaired and maintained by our vendors technocrats using sophisticated technology as per the latest market developments. We also conduct a series of test to ensure its high performance at clients end. The offered Used CNC Vertical Machine is available for the clients at market leading prices.

Features:

- Trouble-free functionality

- Noise-free operation

- Low energy consumption

- Long-service life

Broad Application

- Application Field: Instruments, Electronic Connector, Medical Apparatus etc.

- Machining Range: Short Spindle, Small Disk, High-precision Curve Surface, MF and BSF etc.

- Machining Shape: Cylinder, Cone, Tower-shape, Pear-shape, Pipe &Taper Screw Thread etc.

High Precision:

- Machining Class: Precise Class

- Machining Precision: 0.01mm

- Min. Setting Unit: 0.001mm

High Rigid:

- Guideway Forged by Cast Iron

- Ultrasonic Frequency Quenched Guide Way

- Guide Way Grinded Precisely by Special Guide Way Grinder

High Stability:

- Full-enclosed Cover

- Integral Casted Bed

- Precise Rigid Bearing(Import from USA&Japan)

- 4kw Spindle Motor

High Efficiency:

- X.Z Axes Can be Driven Directly

- Precise Spring Collect Clamping

Technical Specifications

|

Item Specifications |

Unit Parameter |

||||

|

Capacity |

Max. Swing Dia. over Bed |

mm |

340 |

||

|

Max. Swing Dia. Over Slide |

mm |

150 (4 station Electric Tool Post ) |

|||

|

Max. Through Dia. Of Bar |

mm |

38 |

|||

|

Max. Machining Length |

mm |

360 |

|||

|

Thread Range |

Metric |

mm |

0.25-100 |

||

|

Inch |

TPI |

100-4 |

|||

|

Spindle |

Speed Range |

Two Speed |

r/min |

960/1440 |

|

|

Frequency Conversion |

r/min |

200-3000 |

|||

|

Spindle Bore |

mm |

52 |

|||

|

Taper of Spindle |

|

40 |

|||

|

Tube Bore |

mm |

40 |

|||

|

Chuck Dia. |

mm |

160 |

|||

|

Power of Spindle Motor |

kw |

4 |

|||

|

Clamping Device |

|

Standard: Penumatic Collet & Manual 3-jaw Chuck |

|||

|

X.Z Axes |

Travel of X-axes |

mm |

200 |

||

|

Travel of Zaxes |

mm |

450 |

|||

|

Feeding Speed of X-axes(Servo) |

mm/min |

6000 |

|||

|

Feeding Speed of Z-axes(Servo) |

mm/min |

8000 |

|||

|

Power of X-axes Motor(Servo) |

kw |

1 |

|||

|

Power of Z-axes Motor(Servo) |

kw |

1 |

|||

|

Torque of X-axes Motor(Servo) |

Nm |

4 |

|||

|

Torque of Z-axes Motor(Servo) |

Nm |

4 |

|||

|

Min. Setting Unit of X-axes |

mm |

0.001 |

|||

|

Min. Setting Unit of Z-axes |

mm |

0.001 |

|||

|

Tool Post |

Type of Tool Post |

|

Standard: Gang Tool Carriage or 4 station Electric Tool Post |

||

|

No. of Tool |

pc |

4/6 |

|||

|

Size of Tool Shank |

mm |

20x20 |

|||

|

Hydraulic System(Optional) |

Nominal Pressure |

Mpa |

7 |

||

|

Oil-box Volume |

L |

70 |

|||

|

Power of Hydraulic Pump Motor |

kw |

1.5 |

|||

|

Tailstock |

Dia. Of Tailstock Quill |

mm |

55 |

||

|

Travel of Tailstock Quill |

mm |

100 |

|||

|

Taper of Tailstock Quill |

|

MT4 |

|||

|

Other |

Power of Lubrication Oil Pump Motor |

W |

100 |

||

|

Power of Coolant Pump Motor |

W |

90 |

|||

|

Overall Dimension |

mm |

1600(L)x1100(W)x1800(H) |

|||

|

Net Weight |

Kg |

1600 |

|||

|

CNC System |

Standard: Made-in-China(Mainland) GSK: GSK928TC/TE, GSK980TB/TD/TDa Optional: Made-in-China(Taiwan): |

||||

Precision Engineering for Demanding Applications

Designed for exceptional accuracy, this CNC Vertical Machine features 0.005 mm repeatability, making it ideal for precision metalwork and advanced machining tasks. Its robust build and customizable operations suit both prototyping and production environments, increasing output reliability and manufacturing efficiency.

User-Focused Control & Safety

The machine offers a full safety enclosure and operates via a color LCD panel with modern connectivity options, ensuring both operator safety and process convenience. Integrated systems for lubrication and coolant support prolonged, uninterrupted high-speed operation, minimizing maintenance downtime.

FAQs of Used CNC Vertical Machine:

Q: How is the used CNC Vertical Machine maintained for optimal performance?

A: Maintenance is streamlined with its automatic central lubrication system and integrated coolant setup, reducing manual intervention and ensuring consistent operation. Regular checks of air supply and coolant levelsideally before each production shiftare recommended for sustained precision.Q: What is the maximum weight and size of workpieces this machine can handle?

A: The machine supports workpieces up to 800 kg and accommodates workpiece dimensions within a table size of 1100 mm x 500 mm, with travel limits of 1000 mm on X-axis, 500 mm on Y-axis, and 500 mm on Z-axis, providing versatility for various metalworking needs.Q: Where can this CNC Vertical Machine be supplied and installed?

A: Currently available through suppliers, service providers, and traders in India, installation can be arranged on-site by coordinating with the local distributor to ensure compatibility with facility power and air requirements.Q: What types of machining processes can be accomplished with this equipment?

A: The machine is suitable for a range of metalworking operations such as milling, drilling, tapping, and finishing, thanks to the programmable control, high spindle speed, and precision tooling facilitated by its BT40 tool shank and 24-station ATC.Q: When is it most beneficial to use this CNC Vertical Machine?

A: It is particularly advantageous for high-accuracy tasks in precision engineering, batch production, and prototyping environments where programmable operations and reliable repeatability are essential for achieving consistent, top-quality results.Q: How does the operating interface enhance usability?

A: The color LCD panel simplifies workflow integration, supporting program uploads via USB and RS232 ports. This user-friendly interface allows operators to easily set parameters, monitor production, and troubleshoot with efficiency.Q: What are the key benefits of choosing this imported used CNC machine from 2014?

A: Users gain robust construction, efficient programmable machining, and high repeatability at a cost-effective price. The machines imported origin and comprehensive safety features further contribute to reliable, accurate manufacturing with reduced operational risk.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used CNC Machinery Category

Used Industrial CNC Machine

Price 400000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380V, 3 Phase

Manufacturing Year : 2017

Machine Type : CNC Vertical Machining Center

Weight : Approx. 3200 kg

Heavy Duty Used CNC Machine

Price 400000.00 INR

Minimum Order Quantity : 1 Unit

Voltage : 380 V

Manufacturing Year : 2016

Machine Type : Heavy Duty Used CNC Machine

Weight : 4500 kg

Used CNC Profile Cutting Machinery

Price 400000.00 INR

Minimum Order Quantity : 1 Unit

Voltage : 380V

Manufacturing Year : 2018

Machine Type : CNC Profile Cutting Machine

Weight : Approx. 2200 kg

Used CNC Machinery

Price 700000.00 INR

Minimum Order Quantity : 1 Unit

Voltage : 415 V

Manufacturing Year : 2012

Machine Type : Vertical Machining Center

Weight : 4500 kg

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese